GenH2’s Cryo Solution to “Manage the Molecule” for Zero-Loss Hydrogen Transfer

Read Time: 0 minutes

With the bipartisan infrastructure law supporting the build-out of hydrogen production and liquefaction facilities, the hydrogen economy promises to be a major component of the world’s green energy future. It is important to understand that there are major differences between liquid hydrogen (LH2) and gaseous hydrogen (GH2), but the vast majority of people knowledgeable in the industry have come to the conclusion that LH2 is superior. There are several benchmarks to achieve before the promise of hydrogen’s contribution to net zero carbon emissions and clean air can be realized. The first is recognizing that LH2 and not GH2 is the key to build the hydrogen economy.

What Makes Liquid Hydrogen the Key

Controlled storage utilizing active refrigeration provides a regulated internal environment within the bulk storage tank to eliminate the need for venting.

It’s important to understand why industry experts believe so strongly in the advantages of liquid hydrogen versus gaseous hydrogen. Because liquid hydrogen is much denser than compressed gaseous hydrogen, significantly more liquid hydrogen can be transported in a single tanker truck. In addition, the footprint for storage of LH2 is significantly less than that for gaseous hydrogen.

Without the liquefaction of hydrogen before transport, most use cases would not be economically viable. Procuring gaseous hydrogen is the first stage of producing liquid hydrogen and the number of sources is increasing. More methods will evolve for producing a gaseous hydrogen molecule at the site where the input (feedstock) to the process already exist. Examples of this include geologic formations such as expired hydrocarbon reservoirs and shale fields, other locations where natural gas is being flared. Additional locations will focus on where inexpensive or renewable energy can be used to power an electrolyzer that produces hydrogen.

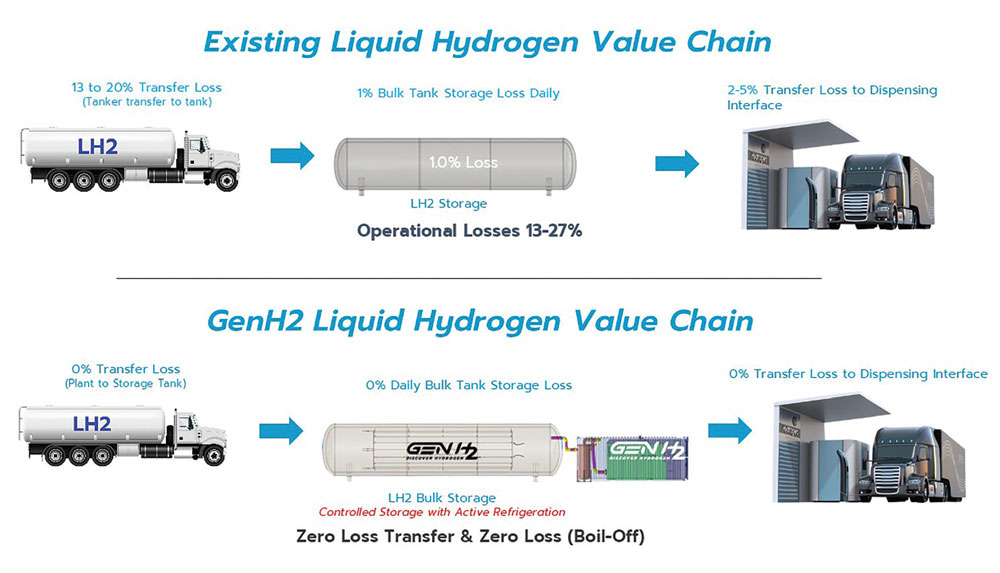

Several barriers to the adoption of LH2 still remain. First, a supply of hydrogen must be accessible and available, without being dependent on a supply chain. This requires a dependable supply of ultrapure liquid hydrogen. Second, we need to be able to deploy safe, low pressure storage of liquid hydrogen. Third, and perhaps most importantly, it will be essential to minimize losses during transfer, storage and dispensing.

The Cryogenic Challenge to Manage the Molecule

A major concern in liquid hydrogen storage is minimizing hydrogen losses from liquid boiloff. Because liquid hydrogen is stored as a cryogenic liquid, any heat transfer to the liquid will cause hydrogen evaporation and require venting once pressure builds. The source of this heat can be ortho-to-para conversion, mixing or pumping energy, radiant heating, convection heating, or conduction heating. Any evaporation will result in a net loss in system efficiency. However, there will be an even greater loss if the hydrogen is released into the atmosphere instead of recovered. Vented hydrogen also increases the effect of greenhouse gases, which in five to ten years may result in financial penalties due to government emissions’ regulation.

The first step in avoiding boiloff losses is to perform an ortho-to-para conversion of the hydrogen during the liquefaction step to prevent any conversion and subsequent evaporation from occurring during storage. Another important step in preventing boiloff is to use insulated cryogenic containers.

Much like comparing a refrigerator to a cardboard box, controlled storage systems and traditional hydrogen storage tanks differ vastly in their capabilities and efficiency. Controlled storage systems provide a regulated internal environment, which ensures stable pressure within the system and eliminates the need for venting. These systems achieve zero loss by enabling complete control over the stored liquid hydrogen, making them an absolute game-changer for global adoption.

Additionally, most people are unaware that the greatest losses tend to occur during the molecule transfer. To better control costs it is important to understand the potential losses that may occur during the value chain and that the ability to ensure zero-loss hydrogen transfer is key to unlocking liquid hydrogen’s potential. The financial consequences associated with vented hydrogen are consequential, amounting to more than 20% loss per transfer, with some measurements reaching 40%. This loss number has earned the hydrogen molecule the “escape artist” label.

Meeting the Zero Loss Challenge

To optimize energy efficiency and output, it is imperative to minimize boiloff losses. When LH2 is delivered to the bulk storage tank, the potential for significant loss during transfer must be addressed. With standard bulk storage transfer systems, the pressure increase requires venting and hydrogen loss. Controlled systems are very efficient as they can also significantly reduce the losses that occur during the hydrogen transfer process. These specialized systems offer the ability to subcool the liquid hydrogen before use to ensure it remains in a liquid state while moving between systems.

Recently, GenH2 debuted zero-loss hydrogen solutions that prevent evaporation and loss. The company’s controlled storage, zero-loss transfer systems were developed based on proof of concepts from NASA. By utilizing a refrigerated storage system, it ensures that liquid hydrogen remains in a subcooled state, by constantly removing heat from the molecule. That process prevents evaporation (boiloff), therefore eliminating the need for venting. This innovative approach not only prevents transfer losses during bulk tank fills but also eliminates daily storage losses and losses that occur during dispensing operations.

With the capability to manage the molecule by producing and storing liquified hydrogen effectively, with zero loss transfer, the tipping point has been reached. The hydrogen economy is here.

This is a re-post from Cryogenic Society of America.