Cryogenic Calorimeter Testing Equipment

Using Advanced Cryogenic Equipment to Test Heat Conductivity

Building on technology developed by NASA, GenH2 Cryogenic Testing Equipment uses a process known as boil-off calorimetry, which measures the amount of heat retained by or transferred through an object. Heat conductivity provides essential information about the thermal properties of materials and systems, as well as their applications.

Advanced Testing Equipment Benefits

- Real-world applications: testing for realistic scientific and industry use cases

- Fast, Precise Results: same-day, reliable, highly accurate testing data

- Ease of Operation: user-friendly devices for a variety of end users

- Flexible and Efficient: enables multiple thermal conductivity tests per day

GenH2 Cryogenic Testing Devices

GenH2’s cryostats utilize boil-off calorimetry to measure heat conductivity by lowering temperatures to cryogenic levels with ultra-cold liquids, such as hydrogen or nitrogen. Heat transfer to the boil-off fluid causes evaporation, allowing for the measurement of heat conductivity in the sample. This data is vital across various sectors, including medical research, refrigeration, food processing, energy storage, aerospace, and education, and is crucial for designing cryogenic and LH2 systems.

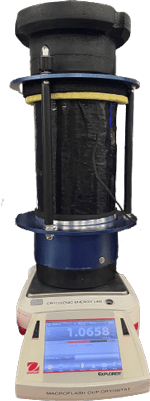

Macroflash

This entry-level cryostat operates without a vacuum chamber, enabling multiple daily thermal conductivity tests. The Macroflash is compact, flat, and small enough to fit on a desk.

Cryostat

- CS100 – A mid-level full-range vacuum testing unit that offers simulation testing, accommodating various boil-off fluids and operating in diverse environments.

- CS900 (shown) – The Advanced Vacuum Simulation Test Platform offers control process simulations, refrigeration design data, and safety assessments to enhance the industry.